Cyclyx Circularity Lab

Cyclyx is Delivering Innovative Solutions for Plastic Waste

Cyclyx is Delivering Innovative Solutions for Plastic Waste

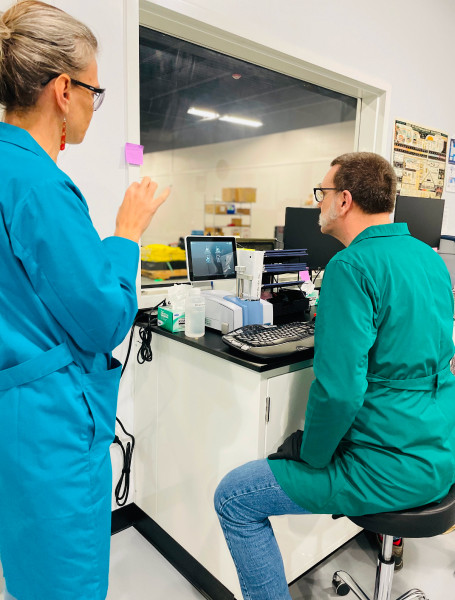

Cyclyx Circularity Lab Director Anita Augustyniak and Lead Lab Technician Mark Rosenqvist review analysis results.

Plastic waste is complex. The chemical composition of plastic materials varies widely, and the contamination of plastic is inconsistent and often unpredictable, which is why traditional recycling operations are selective in the materials they accept and process. The unknowns of plastic waste have prohibited the industry's ability to scale plastic recycling, which has resulted in less than 10% of plastic waste being recycled worldwide today1.

At Cyclyx, we look at plastic differently because we are different. Our Cyclyx Circularity Lab (CCL) in Portsmouth, New Hampshire, is the cornerstone of our 10to90 mission and the innovative work we do in support of the plastic circular economy. Here at the CCL, we test, analyze, characterize, and qualify plastic streams not traditionally accepted for mechanical and advanced recycling use.

Cyclyx Circularity Lab Director Anita Augustyniak and Lead Lab Technician Mark Rosenqvist review analysis results.

A state-of-the-art facility, the CCL was specifically designed to conduct testing of the chemical and physical properties of plastic waste. The variability and complexity of the plastic samples the CCL tests requires novel testing methods and techniques, developed in house, to accurately characterize the plastic waste streams for recycling operations. The information obtained from this testing assists our team in developing programs and recipes of plastic waste that can increase the recyclability of plastics. Our work builds upon an unparalleled 20-plus-year database cataloging the complexity of post-use plastic—polymers, ingredients, manufacturing, and use-related contamination—providing a comprehensive understanding of plastic waste.

In support of the current and future Cyclyx recycling efforts, the CCL staff analyzes hundreds of unique and diverse plastic waste samples that range in size, shape, material, and color. These properties dictate how the team can evaluate and model each sample to determine key characteristics.

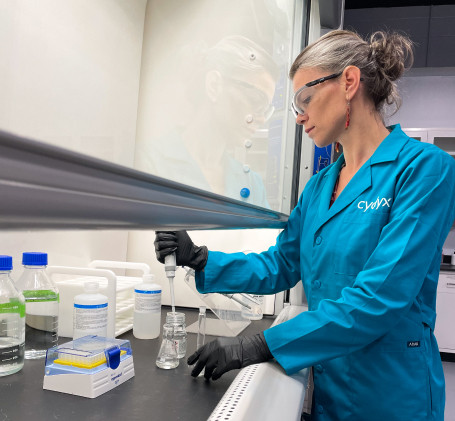

Esteemed scientist Anita Augustyniak preparing a sample for ICP (metal) analysis.

While the CCL has a standard workflow, the complexity and differences of the samples require a tailored approach for handling and analysis—which is beyond any current standard. The learnings from these samples add significantly to the already substantial and expanding Cyclyx plastic database, with over 1,000 new sources tested and tens of thousands of new data points added within just the first year of operation.

The data is made meaningful by the use of the latest advances in technology. Cyclyx is utilizing machine learning and artificial intelligence tools to analyze trends in the data obtained by the lab and operationalize that data through predictive modeling. This enables us to better manage the variability and complexity of plastic waste, create custom recipes, and achieve consistent blends that meet customer specifications in a novel way. This service unlocks the potential to divert more post-use plastic—even those initially deemed too contaminated for consideration—from landfill, incineration, or the environment and reroute it towards existing and new recycling pathways.

Additional Cyclyx Circularity Labs will be built within the forthcoming Cyclyx Circularity Centers. These satellite labs will operate to the same high standards currently in practice at the Portsmouth location, with a focus on quality control and assurance of on-site material to ensure feedstock specifications consistently meet customer requirements.

Please fill out our form, and we will be in touch!